Tech Breakthrough: Revolutionizing Superconducting Wires with FAMU-FSU Innovation

Unveiling the Superconductor Solution

In the quest for perfection, every twist and turn in a wire’s path plays its part. With each defect leading the way to inefficiencies, the groundbreaking work of researchers at FAMU-FSU College of Engineering offers a beacon of hope for manufacturers facing such challenges. This transformative technology, developed in collaboration with industry leaders, marks a new era in superconducting wire design.

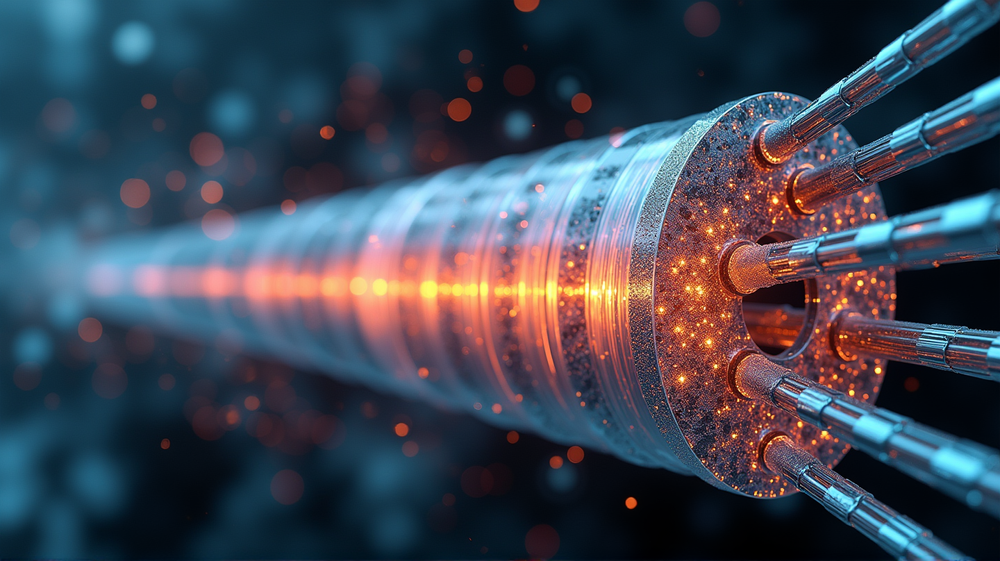

Through an innovative approach, teams at the Center for Advanced Power Systems and the National High Magnetic Field Laboratory devised a new cable architecture. This cable, built from multiple strands of superconducting tape, minimizes fault lines—allowing current to hop across strands with ease. According to Florida State University, this approach mitigates the risk of sporadic defects hindering performance, creating robust and reliable wires.

The Patented Process: How It Works

The heart of the innovation lies in the development of Conductor on Round Core (CORC®) technology. Pioneered in tandem with Advanced Conductor Technologies, these wires showcase unique helically wound bandings of superconducting tape, leveraging the physical contact between these tapes for seamless current flow. Unlike traditional methods that rely on rigid soldering techniques, this design prides itself on flexibility and adaptability.

If flaws are the thorn in the wondrous potential of superconducting cables, then CORC® technology acts as the soothing balm. With a design that champions pressure over solder, each piece of this innovative puzzle ensures the conductive path remains unhindered even when defects arise.

Collaboration: A Symphony of Industry and Academia

This magnificent engineering feat wouldn’t be possible without the harmonious collaboration between FSU and industry titans like Advanced Conductor Technologies and SuperPower Inc. Bridging the gap between research and real-world application, these partnerships channel cutting-edge academic knowledge into the veins of industry, spawning technology that drives progress.

While the initial phases found their footing under the U.S. Small Business Administration’s SBIR/STTR program, success sprints forward with funding from the U.S. Department of Energy. Such synergistic partnerships epitomize how collective expert insights and academic rigor push the limits of what is achievable.

Beyond Electrical Motions: Why It Matters

Superconducting wires have far-reaching implications beyond mere electrical motors. They’re the lifeline of realms as varied as fusion power plants, medical imaging, and magnetic levitation trains. By systematically eliminating costly defects, FAMU-FSU’s blueprint significantly slashes production costs, unlocking vast potential for affordable, high-impact superconducting applications across the board.

With each step forward, this innovation paves smoother paths for future technologies. As researchers like co-author Sastry Pamidi contribute their genius, these dedicated minds do so not in the pursuit of accolades but with a poignant vision for tangible impact—reshaping industries for the better.

The Pioneers and Their Legacy

The labor of Jeremy Weiss, Danko van der Laan, Chul Kim, and their collaborators sketches a testament to the incredible impact of merging advanced scientific infrastructure with pioneering research. Their combined legacy paints a picture of transformative power—all while epitomizing the inclusive, forward-looking ethos of modern engineering.

In the words of Danko van der Laan of Advanced Conductor Technologies, this decade-spanning collaboration marks a turning point, where cutting-edge solutions meet real-world demands, revolutionizing how industries view superconducting wires’ potential.

Ready to experience the future of electrical engineering? Fasten your seatbelt, for this journey through the wires is just beginning.